We are hiring. Join our team today!

DigiFabster Helps i-SOLIDS To Get 200% Monthly ROI

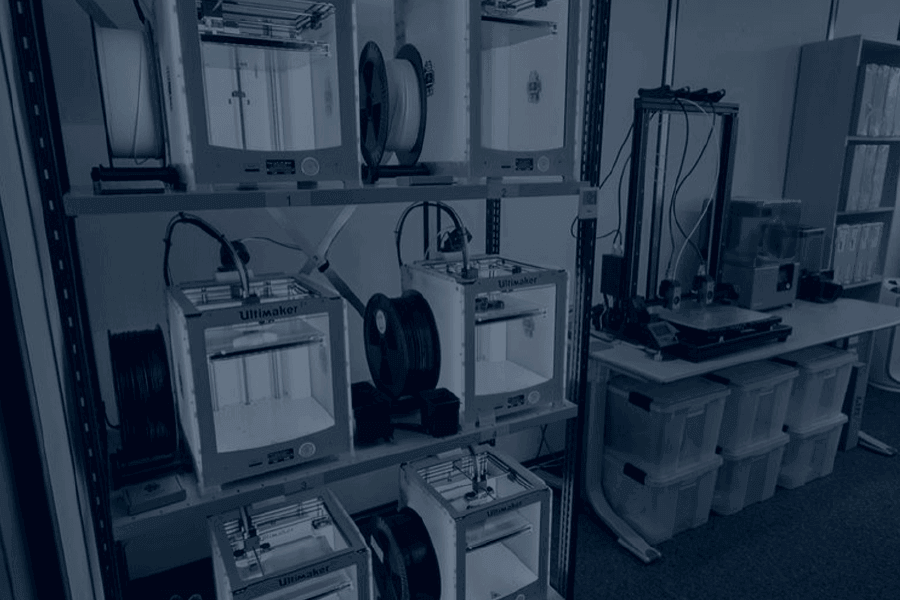

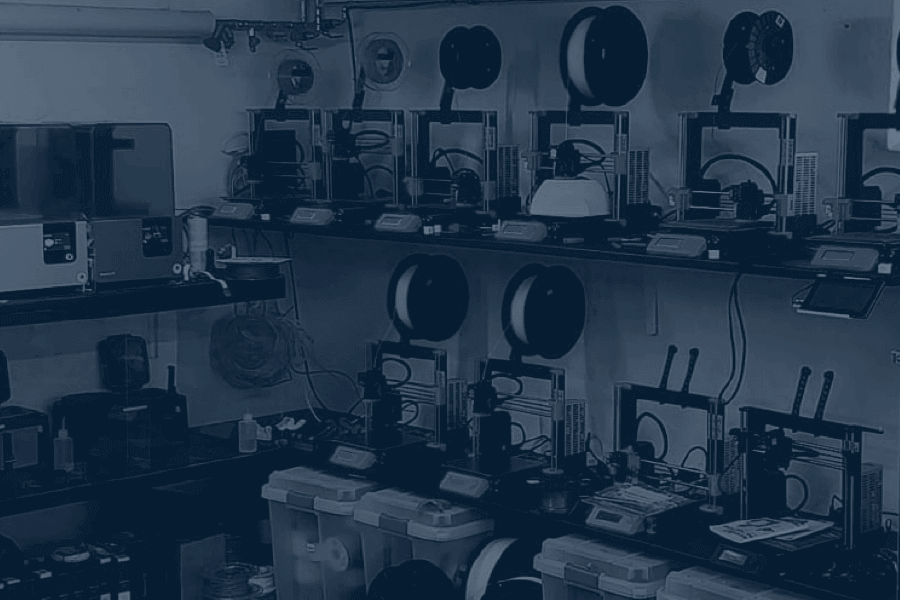

How DigiFabster’s software-as-a-service platform helps 3D printing service bureaus reduce administrative time; better communicate with customers, and improve quality control processesi-SOLIDS (a subsidiary of Knight Engineering Solutions LLC) is a 3D printing service bureau located in the Tomball suburb of Houston, Texas. The firm is made up of a specialized team of engineers, designers, and programmers who provide technical consulting and turnkey prototyping solutions, which include:

- Mechanical and industrial design

- Engineering services (FEA, performance modeling, materials analysis, etc)

- Hardware and software programming

- Project management & intellectual property development

- 3D printing; rapid prototyping and production level additive manufacturing services

i-SOLIDS has a very diverse client base which include consumers, startups and industrial customers. With their extensive engineering experience; i-SOLIDS provides a valuable service to entrepreneurs in many industries. Such industries include: consumer products, restaurants, fashion, medical, energy, and transportation. Given their large printing capacity; i-SOLIDS focuses on customers who need high volume, production quality parts. Their services allow clients to bring new products to market much less cost than with traditional mass manufacturing technologies.

Product Design, Engineering, 3D Printing Service Bureau

Utilize DigiFabster’s software-as-a-service (SAAS) platform to automate quoting and order entry; reducing staff administrative time and improving communication with customers

Create an account; populate and configure the software’s administrative area with the correct pricing and specifications and deploy DidigFabster’s widget on i-SOLID’s webpage. Then market the site’s newfound capability, encouraging prospective customers to request quotes and submit jobs online

Challenge

"Some of our biggest challenges are reducing administrative time and communicating with customers. We offer many different 3D printing capabilities and our clients need to understand the pros and cons of each technology. Each has its own strengths and limitations."

"Some of our biggest challenges are reducing administrative time and communicating with customers. We offer many different 3D printing capabilities and our clients need to understand the pros and cons of each technology. Each has its own strengths and limitations."It’s estimated that only one out of every 1,500 ideas become a product. For most; the upfront costs of product development and mass manufacturing are too steep to overcome. 3D printing has already had an impact, allowing product designers to create lower cost prototypes. But as the technology continues to improve; offering better quality, speed, and economics, inventors, entrepreneurs and other innovators are starting to utilize it in the production of final products.

But with all the hype; service bureaus must also spend a considerable amount of time with prospective clients, helping them understand the advantages and limitations of each 3D printing technology. Further; orders are often more complex than just one simple part manufactured in one single color. Without the right technology in place, service bureaus often must ask customers to submit multiple requests or handle more complex orders via email. This creates more paperwork for service bureaus, driving transaction cost upward.

Solution

"Utilizing the DigiFabster platform has been a great way to reduce the amount of time we spend manually generating cost estimates. It has also helped our customers feel more confident during the ordering process when it comes to selecting materials and other optional print settings."

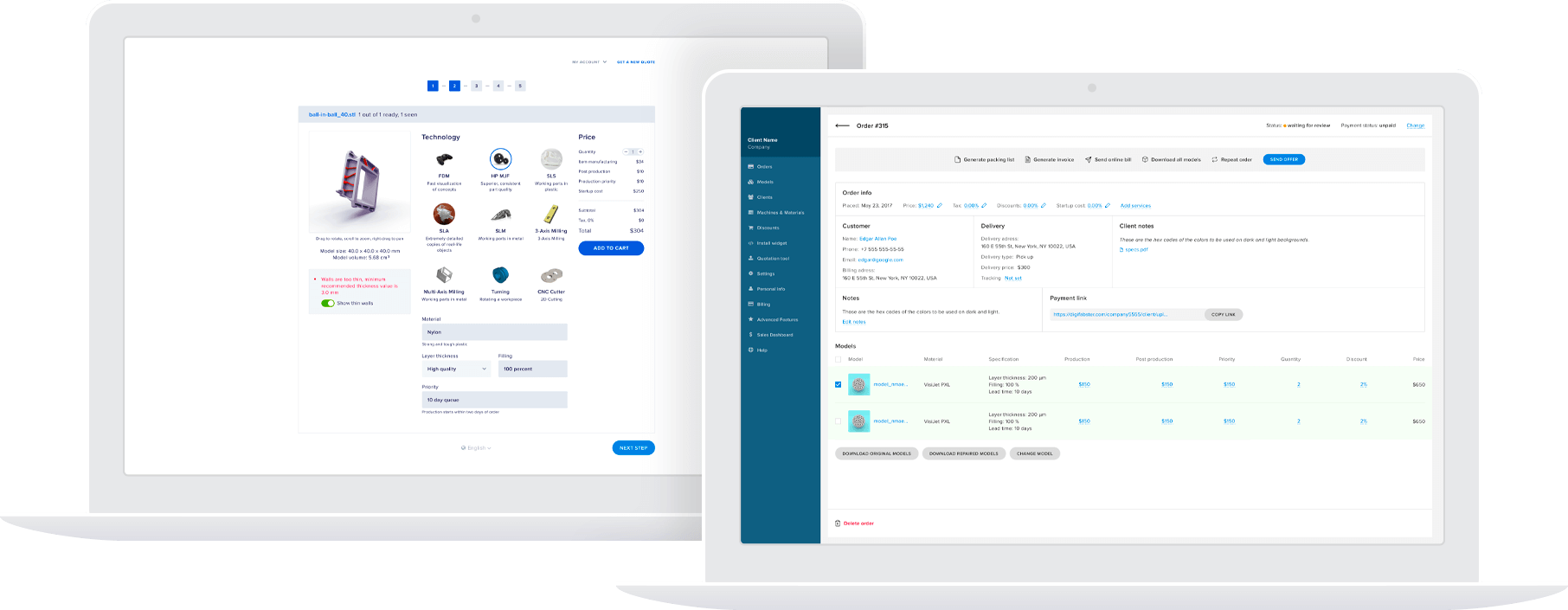

"Utilizing the DigiFabster platform has been a great way to reduce the amount of time we spend manually generating cost estimates. It has also helped our customers feel more confident during the ordering process when it comes to selecting materials and other optional print settings."Once i-SOLIDS made the decision to implement DigiFabster’s software; they were easily able to access the site’s administrative area, add each piece of equipment and establish business rules regarding pricing. The DigiFabster backend also allowed them to determine which customer communications would be automated and which would be handled manually.

When the setup was complete; i-SOLIDS deployed the DigiFabster widget on their website. In testing they found it easy for customers to submit complex orders with multiple parts, and choose other requirements like print resolution, color, and finishing options. When orders were submitted; i-SOLIDS discovered that the amount of paperwork was greatly reduced.

When the DigiFabster system went live; i-SOLIDS found that the orders were being submitted correctly, without significant human interaction. Perhaps more importantly; they found that invoices accurately reflected the original quote, ensuring that customers received the products they had ordered and were billed the amount they anticipated.

Result

"So far; the time we spend on generating estimates has decreased by about 30%. We’re also seeing a 200% monthly return on our investment. Most of that is derived from a reduction in labor costs and an improvement in quality control."

"So far; the time we spend on generating estimates has decreased by about 30%. We’re also seeing a 200% monthly return on our investment. Most of that is derived from a reduction in labor costs and an improvement in quality control."In just the first month using DigiFabster, i-SOLIDS processed 22 orders and over 125 files were uploaded to the system. This led to over $3,200 in online revenue.

DigiFabster’s automation features also helped i-SOLIDS manage the work more profitably. Transaction cost for manually submitted orders can often exceed $75 or more. With an average order value of approximately $150, there simply wasn’t enough margin to support a manual process. By automating the process, they were able to drive the transaction cost significantly lower, enabling them to profitably produce smaller jobs.

“If i-SOLIDS is going to continue to scale and grow, we cannot sacrifice the personalized experience and attention to detail that our customers have come to expect,” says Mr. Knight. “With DigiFabster, we can continue to deliver on our brand promise while simultaneously managing our quality and costs.”

As i-SOLIDS continues to expand; DigiFabster stands ready to provide more advanced workflow solutions, including a powerful application programming interface (API) that enables communication with other software packages. For example; a service bureau like i-SOLIDS could connect its enterprise resource planning (ERP), billing and shipping software, allowing data to be seamlessly shared from the time a job is quoted until it is shipped. Further automating; the workflow can help businesses like these drive transaction costs even lower, while eliminating more of the human error that is common in complex, manual processes.

To learn more about i-Solids, we encourage you to visit their website.

Quick Quote

Learn more about how DigiFabster Quick Quote can help your 3D printing service bureau improve the customer experience, while reducing costs and generating more revenue