We are hiring. Join our team today!

DigiFabster Helps Cubic Inch Turn Quotes in 5 Minutes, Instead of 24 Hours

The combination of DigiFabster’s software and HP’s Multi Jet Fusion creates a win-win for Cubic Inch and their clients, saving time and enabling faster productionIntro

"Our main goal is to help clients realize the full potential of 3D printing technology. We enable them in two key ways. First of all we help clients find applications that will bring the greatest value to their business. Then we help them to implement additive manufacturing into their supply chain by optimizing part geometry and recommending the best manufacturing technology"

"Our main goal is to help clients realize the full potential of 3D printing technology. We enable them in two key ways. First of all we help clients find applications that will bring the greatest value to their business. Then we help them to implement additive manufacturing into their supply chain by optimizing part geometry and recommending the best manufacturing technology"Cubic Inch is an engineering and manufacturing company headquartered in Warsaw, Poland. They work primarily with the automotive industry and its suppliers.

Cubic Inch offers a range of services for its clients. From an engineering perspective, they not only design products and parts, but also provide 3D scanning and reverse engineering. The firm also helps its clients optimize the geometries of their parts for additive manufacturing.

On the manufacturing side, Cubic Inch typically produces parts using HP’s Multi Jet Fusion 3D printing technology. This allows them to offer a speed-to-market advantage others can’t match, often allowing them to deliver finished parts in two to five business days.

Engineering and Advanced Manufacturing

Utilize software to speed up the process of quoting and jub submission, freeing up staff to focus on higher value work

Identify and implement the ideal software solution to meet the firm’s unique requirements, helping Cubic Inch and its customers conduct business more quickly and with less friction

Challenge

"Manual quoting in additive manufacturing is a pretty simple but time-consuming process. The problem is that we realize a lot of comparatively small orders. We had one full-time employee who was responsible only for quoting. We tried some other quoting apps before and none of them met our requirements"

"Manual quoting in additive manufacturing is a pretty simple but time-consuming process. The problem is that we realize a lot of comparatively small orders. We had one full-time employee who was responsible only for quoting. We tried some other quoting apps before and none of them met our requirements"While the process of producing a quote is fairly straightforward, a significant amount of data must be collected from a potential customer before a price can be determined. First, a file must be received. This allows a service bureau to determine the part’s size, volume and other dimensional information. It also allows the shop to identify the part’s orientation and other factors that can impact how the piece is produced.

Beyond the file, customers must supply other specifications, such and material and quantity of parts to be quoted. Shops typically also require contact and other business-based information. Collecting all of this can sometimes take a series of phone calls or back-and-forth emails.

Then, once a customer is ready to place an order, additional information such as payment and shipping methods must be communicated. In a manual environment, much of this is handled with spreadsheets and other disparate software. It can create a lot of duplicate work and confusion as project managers attempt to move work through the facility and maintain communication with customers.

Solution

"As part of their due diligence, lots of firms want to compare 3D printing with the cost of other manufacturing methods. Online quotation helps speed this process up significantly. DigiFabster offers a win-win solution. Both the client and the company benefit. On the business side we save a lot of time on quoting and order entry, allowing our team to focus more on demanding tasks like improving part quality. Our clients also benefit from DigiFabster’s solution. When we had to prepare offers manually, it often took 24 hours or more to turn a quote. Now it takes about 5 minutes for our customers to have an offer in their hands"

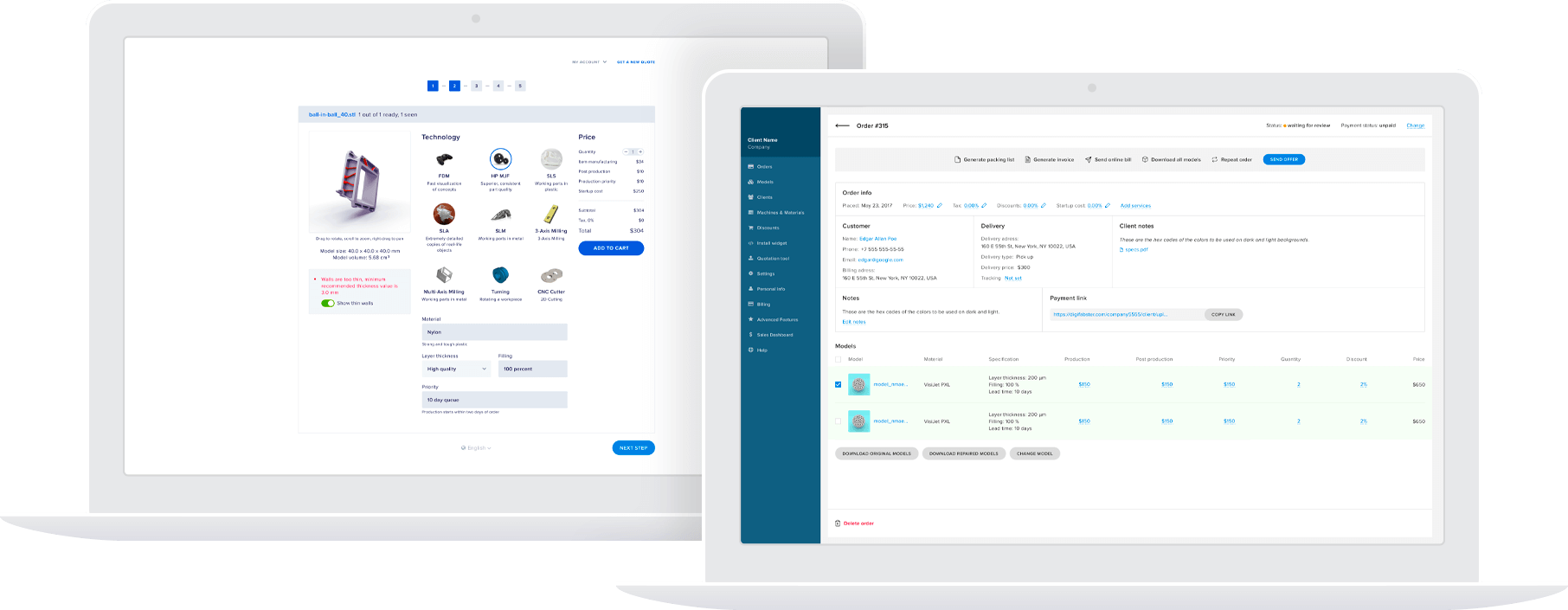

"As part of their due diligence, lots of firms want to compare 3D printing with the cost of other manufacturing methods. Online quotation helps speed this process up significantly. DigiFabster offers a win-win solution. Both the client and the company benefit. On the business side we save a lot of time on quoting and order entry, allowing our team to focus more on demanding tasks like improving part quality. Our clients also benefit from DigiFabster’s solution. When we had to prepare offers manually, it often took 24 hours or more to turn a quote. Now it takes about 5 minutes for our customers to have an offer in their hands"Cubic Inch researched the market and found DigiFabster to be a viable solution for it’s online quoting requirements. Since DigiFabster’s offering is Software-as-a-Service, it was easy for them to select the features and capabilities they needed for their business. Once they signed up, the team at Cubic Inch was able to easily configure the software to mimic their pricing model.

Once they tested the variables to ensure pricing was correct, Cubic Inch used DigiFabster’s iFrame widget to install it on their website. In a matter of a few hours they were ready to begin quoting and selling online.

Result

"In my role with Cubic Inch, I am ultimately responsible for generating new business. We are always looking for effective ways to engage new clients. DigiFabster plays a very important role in helping us execute our strategy"

"In my role with Cubic Inch, I am ultimately responsible for generating new business. We are always looking for effective ways to engage new clients. DigiFabster plays a very important role in helping us execute our strategy"With their new online quotation tool in place, Cubic Inch began marketing their services and working with existing customers to help them utilize the new system. The solution quickly delivered the win-win benefits they envisioned. Not only were customers saving time, but the company experienced astonishing improvements in productivity and growth.

First, Cubic Inch was able to reduce the cost of preparing a quote by 50% when compared with producing them offline, manually. Also they were able to reduce the overall time it took to finalize and submit a quote from 12 hours down to 1 hour, an average which includes the smaller number of offline quotes that must still be managed. Finally, Cubic Inch is now delivering 20% more quotes per month, helping them grow more revenue more profitably.

Cubic Inch also sees opportunity for further enhancement.

“We can’t wait for DigiFabster to offer a production management module,” says Mr. Stefańczyk. “If that were to happen, we could manage our entire order workflow with one solution. But for now, it’s nice to know we can integrate DigiFabster with other software packages.”

For its part, DigiFabster is excited to have customers like Cubic Inch, who not only use the product successfully, but also contribute to its future development.

“Cubic Inch is exactly the type of customer we’re looking for,” says DigiFabster CEO, Constantine Ivanov. “They encourage us to continuously improve our product. It's a challenge we gratefully accept. Our goal is to provide the industry’s best workflow solution. Customer input is a vital tool in helping us achieve that objective.”

For example, some of DigiFabster’s customers provide work for the defense and aerospace industries. This requires them to be ITAR compliant. To help meet those needs, DigiFabster offers an On Premise solution that provides the additional security and features those clients require.

At the same time, DigiFabster understands that workflows at machine shops and 3D printing service bureaus are complex and often require multiple tools. To help its clients eliminate redundancy and automate as much of their operations as possible, DigiFabster offers complete API integration, enabling its clients to connect quoting and order management with many other popular types of software including CRM, ERP, shipping, billing and payment applications.

To learn more about Cubic Inch, we encourage you to visit their website.

Quick Quote

Learn more about how DigiFabster Quick Quote can help your 3D printing service bureau improve the customer experience, while reducing costs and generating more revenue